Organic and printed electronics has developed into a global market worth more than 35 billion dollars. While OLED displays currently play the biggest role, in the coming years strong growth is expected in other applications such as NFC/RFID, sensors, wearable electronics, and in the automotive and medical industry sectors. These trends are also reflected in the eighth edition of the Roadmap published by the OE-A (Organic and Printed Electronics Association), a working group within VDMA.

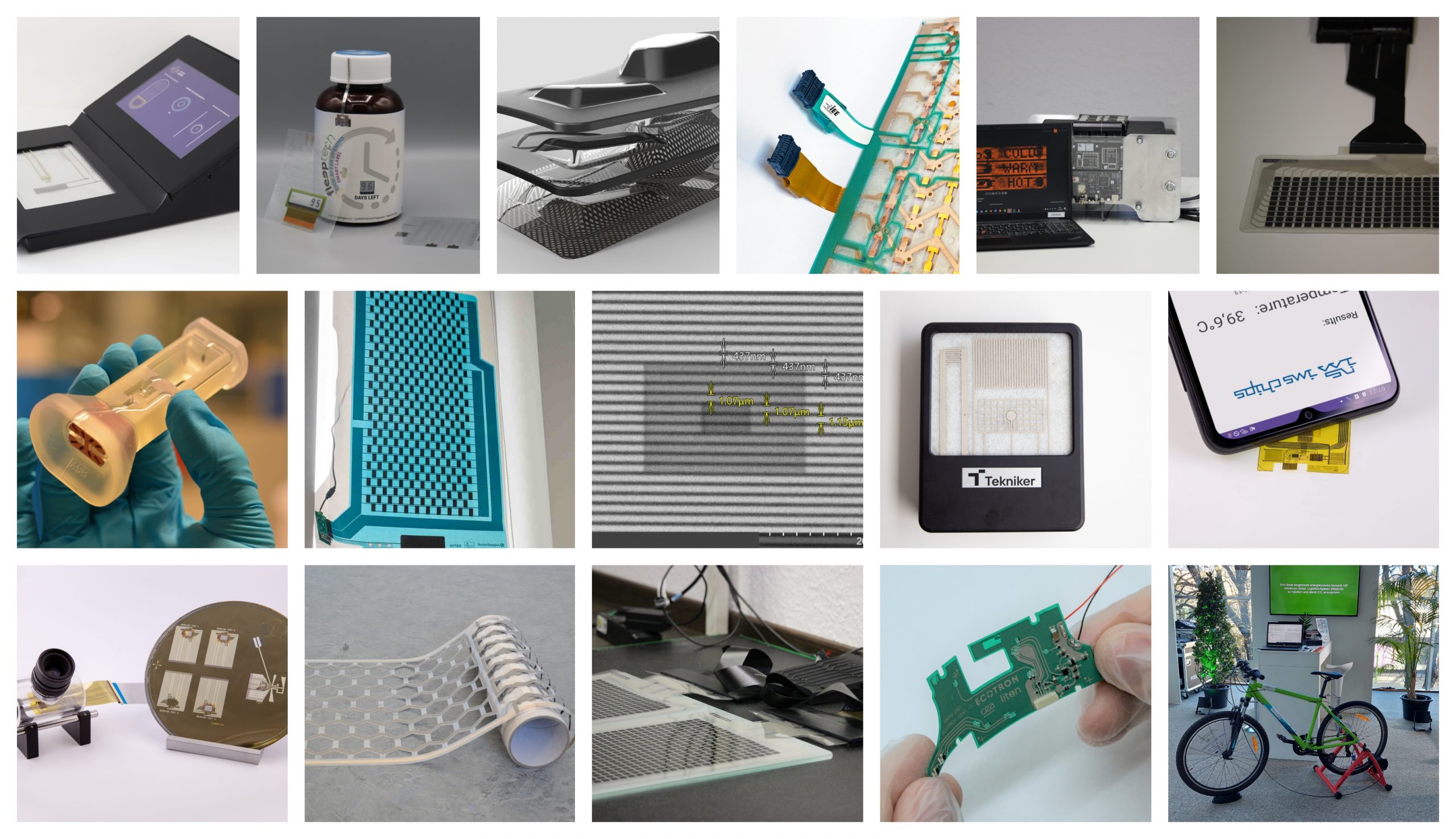

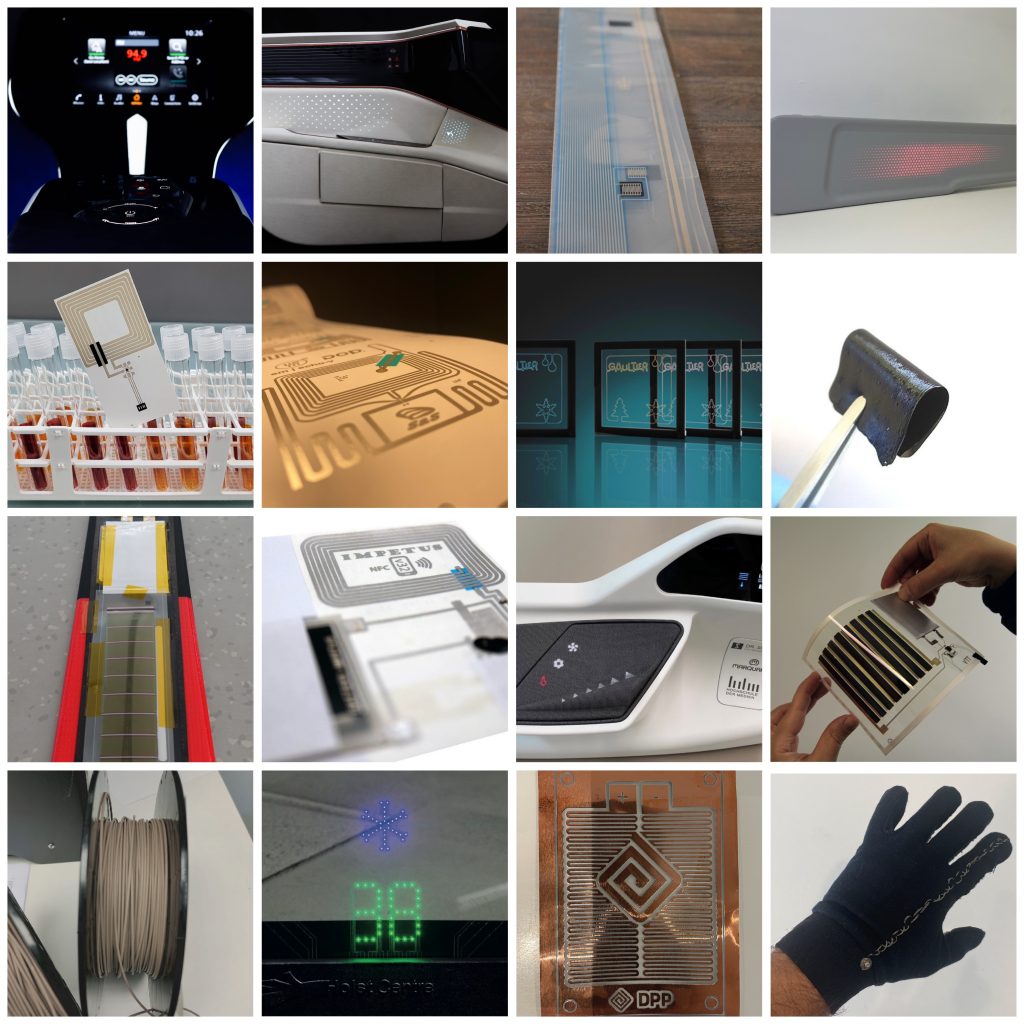

The revolutionary technology of organic and printed electronics is constantly opening up new fields of application and has already established itself in many areas. From Internet of Things (IoT) to Consumer Electronics and Healthcare, the Automotive industry, Smart Packaging and Buildings: Printed electronics is now applied in numerous products and industries worldwide. While a few years ago the use of printed electronics in the Automotive industry was for example limited to seat occupancy sensors and OLED taillights, the technology is now finding increasingly more applications in this sector, such as in the form of touch sensors or heating foils. The current White Paper “OE-A Roadmap for Organic and Printed Electronics” takes a closer look into the advanced maturity of the printed electronics industry. For the first time, the experts of the OE-A have compiled detailed short-, medium- and long-term forecasts for the above-mentioned industry sectors in addition to the latest developments. “We see a clear trend away from the technology push of earlier years towards an increased market pull of organic and printed electronics today,” says Dr. Klaus Hecker, OE-A Managing Director.

Hybrid Systems enable new applications

Printed electronics complements classical electronics, which enables new applications by offering additional technical and design freedom. An important development identified in the OE-A Roadmap are Hybrid Systems that combine printed and classical silicon-based components. This combination can be used especially for Internet of Things, Smart Labels and also in the Healthcare sector. “Products that combine both technologies will make a major contribution to the further establishment of printed electronics on the market and the creation of new applications,” explains Hecker.

Mastering challenges to further develop the industry

The White Paper also identifies challenges that still need to be overcome in order to achieve a breakthrough in other fields of application. “In recent years great progress has been made with functional materials. In the future, printed electronics will also be used increasingly on three-dimensional surfaces, as well as in clothing or as intelligent plasters on the skin. This means that materials as well as substrates and encapsulations must be stretchable. There is still a considerable need for development here,” explains Hecker. In order to increase the suitability for mass production, further progress is also required in the optimization and scaling of production processes, yield, and standardization. The OE-A Roadmap is an important compass for industry, politics and science in development and product planning.

The OE-A Roadmap White Paper is now available on the OE-A website.